PCB Assembly Capabilities Include

- Expertise in single, multi-layer flexible, and rigid circuit boards.

- In-depth knowledge of various application requirements.

- Proficient in surface mounting, through-hole, and mixed technology.

- State-of-the-art advanced manufacturing equipment.

- Stringent quality inspections.

- Passive components 0201 and higher.

- Active components from 0.35mm pitch.

- BGA, micro-BGA, QFN, CSP, and any leadless devices up to .35mm pitch assembly with 100% 3D X-ray inspection.

- Solder Type (Lead-free – RoHS).

- Automatic Single- or double-sided component placement.

- Visual Inspection, Solder Past Inspection (SPI), X-ray inspection BGA Placement-microscope inspection.

PCB Assembly Line

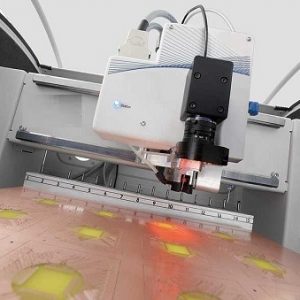

We have been striving to acquire local manufacturing capabilities for all kinds of electronic assemblies. For this purpose, we have deployed an automated PCB SMT & THT assembly plant along with rework and inspection systems.

Our Assembly Lines feature various setups, suitable for different production requirements. The lines consist of the below equipment:

- Automatic Stencil Printer.

- SPI (Solder Paste Inspection System).

- High-speed Pick-and-Place Machine.

- 12 Heat-Zone Reflow Machine.

- Automatic Optical Inspection System.

- X-Ray inspection.

- Wave Soldering for THT.

Reviews

There are no reviews yet.